- #SECTION VIEW IN MASTERCAM 2019 INSTALL#

- #SECTION VIEW IN MASTERCAM 2019 DRIVER#

- #SECTION VIEW IN MASTERCAM 2019 MANUAL#

- #SECTION VIEW IN MASTERCAM 2019 FULL#

- #SECTION VIEW IN MASTERCAM 2019 WINDOWS 10#

#SECTION VIEW IN MASTERCAM 2019 INSTALL#

We anticipate that Mastercam will be the last release to officially support Windows 7 as Microsoft is ending extended support for the OS in January We anticipate the new versions of Mastercam will still install on Windows 7 until the release of Mastercam The processor speed will impact how fast the software will calculate and complete tasks. While Mastercam may run on other Windows editions such as Home Edition or virtual environments such as Parallels for Macit has not been tested on these configurations and is therefore not supported.

#SECTION VIEW IN MASTERCAM 2019 WINDOWS 10#

We recommend using Windows 10 version or later bit Professional editions. Connection to Internet and email is recommended for installation, support, and updates.ĬNC Software continues to review the operating system OS requirements for Mastercam with a goal of providing the best possible user experience for our customers. Our recommendation is to get as much power processor, video card, and memory for your systems as you can afford. These recommendations are based on systems we have in use at CNC Software for testing and evaluation purposes. See the table below for minimum and recommended system configurations for Mastercam. Mastercam Mill-Turn allows you to have a complete post, additional tools made for those machines like pinch and balanced turning, and ease of use for twin spindle, twin turret, and B-axis head machines. Extend tool life with proprietary toolpath strategies that maximize material removal rate and reduce cycle times.

Optimize machine movement and synchronization between turrets and spindles with this state-of-the art interface to generate accurate and efficient code. Machine Simulation is a safe way to prove out 3-axis, 4-axis, or 5-axis toolpaths to make clean, efficient, and accurate programs.

#SECTION VIEW IN MASTERCAM 2019 DRIVER#

Grab driver hackĭetect collisions between your stock, tool, and machine components before sending code to your machine tool.

#SECTION VIEW IN MASTERCAM 2019 FULL#

A full design package based on a machinists needs including wireframe, surfaces, and solids design open most CAD file in Mastercam to access modeling and prep tools for CAM programmers to get parts on and off machines quickly. Mastercam Mill-Turn provides a custom machining environment in which the machine configuration and limits are captured and displayed graphically to ensure safety and quality. MasterCAM 2019 Tutorial - 3,5 & 4 Axis Simulation g code You can use Mill-Turn to machine parts without fear of costly collisions or machine damage. This lathe mill combination programming software provides a set of routines to program complex parts and test your cutting strategies in a single environment- before your stock is on your multitasking machine.

#SECTION VIEW IN MASTERCAM 2019 MANUAL#

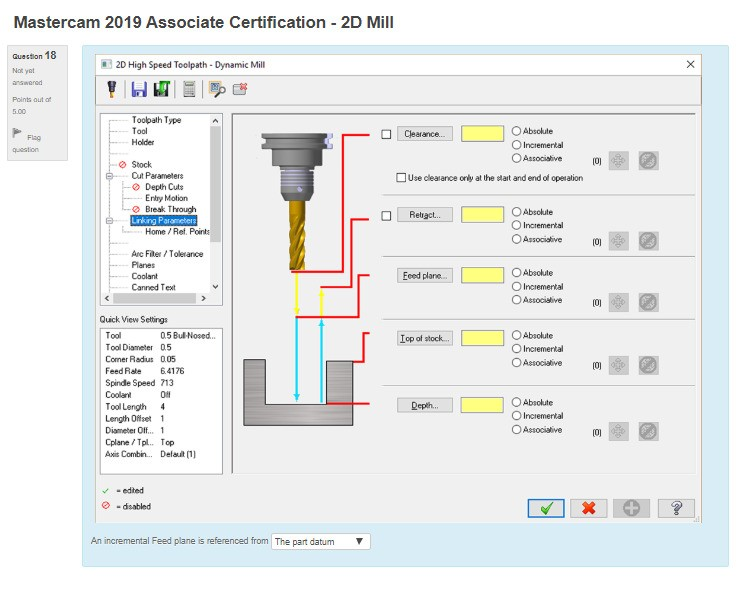

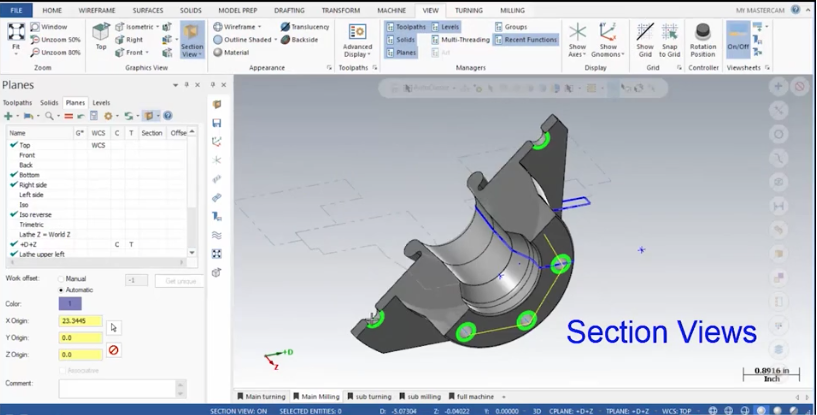

These multitasking CNC machines reduce multiple setups, manual part handling, redundant fixturing, and idle time for improved productivity in manufacturing. See our privacy policy.Mastercam Mill-Turn programming streamlines high-power multistream machine centers for increased performance and safety. By continuing to browse or use this site, you are agreeing to our use of cookies. This site uses cookies to enhance your website experience. For more information on Mastercamplease visit www. New toolpath visualization capabilities and section view tools, improvements to view and setup sheets, and a wide array of system level enhancements improve efficiency in managing job workflow, as well as providing better tools for process documentation.

Job Management and Documentation Mastercam also improves job documentation and management, while helping to address quality and certification initiatives. These improvements include support for block drilling multiple holes simultaneously and better axis control in simulation, allowing you to easily check machine limits or collision checking. Validation With improvements to toolpath and machine simulation, toolpath graphics, and other verification and analysis tools, Mastercam provides greater programming assurance and allows for better, more informed decisions before a job is run. Job Preparation and Setup Mastercam increases efficiency and reduces job setup time and the preparation needed for part machining and programming.

New milling toolpath strategies, like the high speed Equal Scallop toolpath, offer both machining performance and surface finish improvements. Re-engineered chamfering and holemaking strategies, plus the new Multiaxis deburring provide new levels of time-saving automation and simplicity. Coesd 2010ĬNC Programming Mastercam continues to increase productivity and programming efficiency, while reducing overall production costs, with a series of automated 2D through 5-axis toolpath improvements. Mastercam was developed to streamline the manufacturing process from job setup to job completion.

0 kommentar(er)

0 kommentar(er)